Buy calibration weights

Calibration weights are required for calibrating scales. If you want to buy calibration weights, you should find out in advance which accuracy class is required. Calibration weights" is only a generic term for fine weights, precision weights or commercial weights. In most cases, a calibration weight (commercial weight) of class M1 is sufficient.

Buy calibration weights in online store

For companies in which goods or merchandise are regularly sold by weight or in logistics companies where the actual shipping weight plays a decisive role, it is important to ensure that the scales used comply with the calibration regulations, i.e. are calibrated. Depending on the quality assurance requirements, weights of different classes are needed for this purpose.

We, the graviCAL company, have specialized in precisely this area with our in-house laboratory and are able to calibrate calibration weights in accordance with DAkkS.

Calibration weight for calibrating a bench scale

Bench scales are factory calibrated, but it is recommended to check the accuracy of the scale at regular intervals. As part of the company's internal quality assurance, scales are tested within their measuring ranges. A calibrated table scale with a weighing range of e.g. 15 kg and a graduation of 0.2 grams should be checked at least with test weights of class M1 calibrated according to DAkkS. We recommend carrying out the check with calibration weights in the following steps: Position the balance on a weighing table and check it in different weight ranges (from 1 kg to 15 kg). For the above-mentioned bench scale we recommend a set of weights of class M1, which has a tare weight of exactly 10 kg and consists of calibration weights 1 kg, 2x2 kg, 5 kg. Alternatively, a block weight with 5 kg is also suitable as a supplement.

Differences - factory calibration, calibration (according to DAkkS) and verification

Factory calibration

Factory calibration is not regulated by law. It is used to ensure that a scale is used in accordance with its quality and to reduce errors during weighing.

What can be factory calibrated?

In short: Test equipment and measuring instruments that are not subject to a calibration routine according to DAkkS and are not subject to calibration. The procedure is not specified. The factory calibration can be carried out, for example, analogously to the conformity assessment (calibration).

The measurement deviations are specified using calibrated weights. After performance, a factory calibration certificate is issued. A factory calibration can be performed as often as the operator of the measuring instruments and test equipment deems appropriate. According to 9001:2015, the user determines the cycle after use. Similarly, DIN EN ISO 9001:2015 (7.1.5.2) leaves it up to the user to select the appropriate test procedures. As a rule, a factory calibration is sufficient, provided that traceable test equipment has been used.

Calibration (according to DAkkS)

Calibration according to DAkkS specifications is not regulated by law. If the test weight or balance is used within a quality management process, calibration according to DAkkS specifications should be performed beforehand. All error-free test equipment can be calibrated according to DAkkS.

But how does calibration according to DAkkS work? A DAkkS-accredited laboratory tests the test equipment for correctness by tracing it back to internationally recognized standards. Such a calibration may only be carried out by highly qualified personnel who have presented themselves to the DAkkS certification body. A calibration certificate is then issued, the international recognition of which is guaranteed by multilateral agreements on mutual recognition between EA (European co-operation for Accreditation) and ILAC (International Laboratory Accreditation Cooperation). In Germany, this is monitored by the German Accreditation Body (DAkkS). The operator of the measuring instruments and test equipment is responsible for compliance with the respective recommended periodic recalibration intervals.

Calibration

Calibration is regulated by law. It is mandatory as soon as one participates in so-called "legal metrology". This includes, for example, the sale of goods by weight, the calculation of charges by weight, and the manufacture or inspection of prepackages, etc. You will find further information on this in the Verification Act.

Only "legal for trade" scales with type approval and test weights that comply with the OIML (Organisation Internationale de Métrologie Légale) requirements can be calibrated. During verification, scales and weights are checked for verification error limits (maximum permissible errors). This is done by the manufacturer (only in the case of manufacturer's verification) and the weights and measures office (within the legally prescribed intervals). A stamp certifies that the measuring instrument met the requirements at the time of testing and that it remains "correct" when handled in accordance with the rules of technology within the recalibration period. For the European Union, a declaration of conformity with CE marking is considered "initial verification". Nationally, only recalibration and national declaration of conformity are recognized. The recalibration periods for test equipment and measuring instruments are defined by the legislator in national specifications.

Where can I find the accuracy class of a scale?

The accuracy class of a scale can usually be found on the bottom of the product. The label that confirms that your scale has been verified at the factory also indicates the accuracy class.

When selecting the calibration weight, it is important to choose the appropriate calibration weight, the following calibration weights are available:

Calibration weight as single weight of class M1

- Calibration weight 1g

- Calibration weight 2g

- Calibration weight 5g

- Calibration weight 10g

- Calibration weight 20g

- Calibration weight 50g

- Calibration weight 100g

- Calibration weight 200g

- Calibration weight 500g

- Calibration weight 1kg

- Calibration weight 2kg

- Calibration weight 5kg

- Calibration weight 10kg

- Calibration weight 20kg

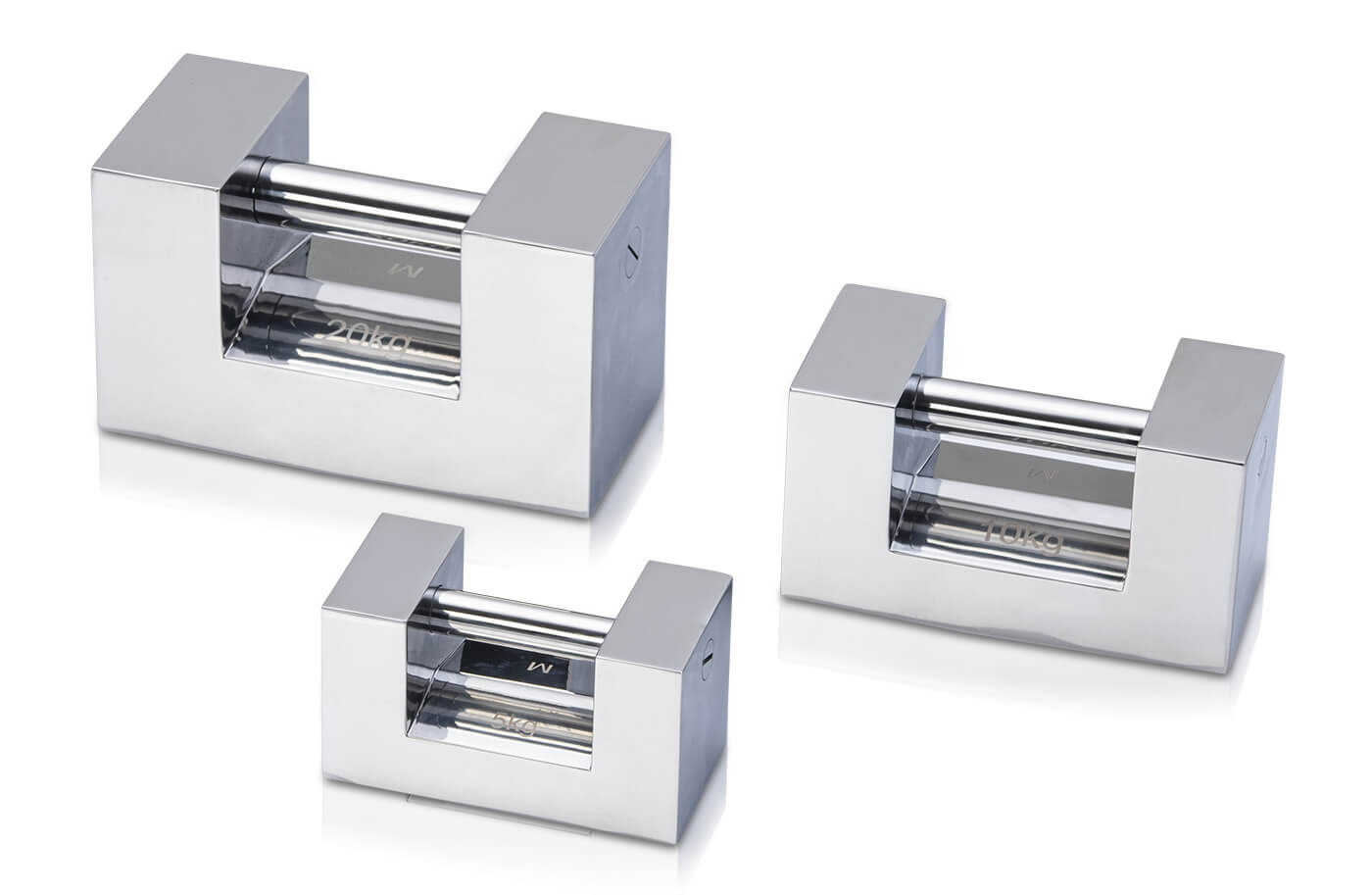

Calibration weights as block weights in class M1

- Calibration weights 5 kg block weight

- Calibration weights 10 kg block weight

- Calibration weights 20 kg block weight

Advantages of calibration weights as block weights

Since calibration weights have a high accuracy, as well as tolerances in the range of 250mg (for a calibration weight of 5kg), careful handling is of the highest priority. The integrated handle makes it particularly easy and gentle to handle the weights. In addition, we recommend storing the calibration weights in the aluminum case.

Does a scale have to be recalibrated?

A scale does not necessarily have to be recalibrated, it is often sufficient to check or control the scale with calibration weights. Basically, industrial and commercial scales fall into this range. Calibration weights are divided into classes. For the verification of a class III (3) scale, a calibration weight M1 with an accuracy ≥ 10,000 e is required. Those who wish to calibrate or calibrate their precision scales of class II (2) require calibration weights for scales that correspond to calibration class II (2) ≤ 30,000 e. Here, calibration weights of this precision are referred to as so-called fine weights, fine weights are indicated with the class F1, F2. Calibration weights should always be handled with care.

Calibrated scales can be found at bosche.eu in the online store.